IndustriElectric

High Temperature Infrared Sensor, Non-Contact, 4-20mA Output

High Temperature Infrared Sensor, Non-Contact, 4-20mA Output

Couldn't load pickup availability

High temperature infrared sensor at factory price for sale, with 4-20mA signal output, can be used for temperature monitoring in chemical industry, metallurgy, food, textile industry and other fields. Measurement range -50℃ ~ 300℃ (-58 ~ 5720F), accuracy ±2% or ±2℃. This IR temperature sensor with infrared measurement, easy assembly and high precision.

Industrial high temperature infrared sensor, non-contact with -50℃~300℃ measuring range, infrared measurement, M12 connector, millisecond response speed, can monitor temperature continuously, small in size, easy to install, suitable for temperature monitoring in steel, glass and plastic production areas.

Specification

| Model | ATO-BRW600-402 |

| Measurement Range | -50℃ ~ 300℃ (-58 ~ 572°F) |

| Measuring Distance | 10 ~ 30 cm |

| Power Supply | 24VDC, 50mA Max |

| Accuracy | ±2% or ±2℃ |

| Emissivity | 0.95 |

| Signal Output | 4–20 mA |

| Working Temperature | 50℃ |

| Response Time | 500 ms |

| Response Wavelength | 8~14 μm |

| Maximum Current | < 50 mA |

| Storage Temperature | -20 ~ 50℃ |

| Ambient Temperature | 0 ~ 50℃ (Better performance in this range) |

| Relative Humidity | 10 ~ 95%RH (No condensation) |

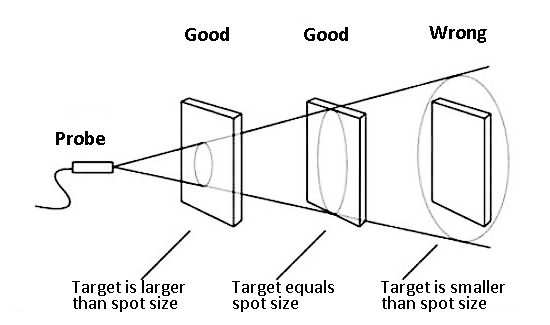

| Object Distance Ratio | 16:01 |

| Protection Grade | IP65 |

| Dimension | L168mm × φ50mm |

| Electrical Connection | M12 Connector |

| Shell Material | Aluminium Alloy + Stainless Steel |

| Weight | 1 kg |

Dimension & Wiring

Unit: mm

Detail

Application

Widely used in electric power equipment; modern medical field; food industry; chemical industry; construction industry; machining control field and other temperature control scenarios.

Tips for installing the non-contact infrared temperature sensor

- According to the measurement requirements and the measurement coefficient of the infrared temperature sensor, select the appropriate distance and orientation, and fix the infrared temperature probe and the adjustment bracket well.

- Adjust the measurement direction of the probe so that the measured object is roughly facing the observation site.

- Lock the orientation of the adjustment bracket.

Share